In this blog, Pampi Paul, Mahesh B Tengli, N Uttam Singh, Anirban Mukherjee, A Roy and CH Gowda discuss the use of Life Cycle Assessment in understanding the distribution of resource demands and environmental impacts along food product supply chains. This method is also used as a way of identifying environmental hotspots so as to develop management strategies that can improve the supply chain.

CONTEXT

In recent times, energy consumption by different applications is growing rapidly, resulting in the generation of significant quantities of waste and emissions that is left in the environment. Meanwhile, the term ‘sustainable development’ has prompted initiatives with different methods for assessing impacts, including environmental, social or economic impact of any process, product, etc. With increasing attention paid to sustainability issues, in agriculture as well as food sector, has come a rising interest in metrics for measuring the environmental profiles of food production system. Therefore, it is essential that governmental authorities around the world take vital steps to apply the necessary practices and regulations that can help reduce energy consumption and thus the impact on the environment.

LIFE CYCLE ASSESSMENT

Life Cycle Assessment (LCA) is a formalized methodology (ISO 14040-14044) that provides a quantitative approach to understanding the distribution of resource demands and environmental impacts along food product supply chains, as well as key mitigation levers. The purpose of this kind of LCA is to develop a baseline understanding of the magnitude, distribution of resource demands, and environmental impacts associated with production of a given commodity at a regional or national scale, along with key levers for mitigation actions. The life cycle approach is essential for effective environmental management because important interactions may occur ‘upstream’ or ‘downstream’ along supply chains.

In the context of sustainable agriculture, assessing the impact of farming practices has become important. Life Cycle Assessment (LCA) thus offers a comprehensive method for assessing the environmental impact of a product or an activity over its entire life cycle. The purpose of conducting LCA studies varies from one application to another. Different applications use LCA for different purposes. In general, the main aim of using LCA is to reduce the environmental impact of products by guiding the decision making process towards more sustainable solutions.

LIFE CYCLE ASSESSMENT APPROACH TO QUANTIFY THE EMISSION FROM DAIRY FARMING

On a global level, agriculture is estimated to be the fourth contributor of greenhouse gases (GHGs) after energy supply, industry, and forestry (IPCC 2007). A report issued by FAO (Steinfeld et al. 2006) identified livestock as being responsible for 18 percent of the world’s total GHG emissions. The most important GHGs generated by dairy industry are methane, nitrous oxide, carbon dioxide and some refrigerants, such as HFCs and CFCs (Vora 2010), and the major source of methane (CH4) emission is from enteric fermentation of animals (Hospido 2005). Nitrous oxide (N2O) emission occurs due to production and use of fertilizer and manure storage; and carbon dioxide (CO2) emission occurs due to the use of energy sources at farms as well as at the processing level (Thomasen et al. 2008).

| Box 1: Carbon Footprint ‘Carbon footprint’ is the total amount of greenhouse gas emitted directly or indirectly caused by an activity or is accumulated over the life stages of a product; it is measured in terms of Carbon di-oxide equivalent (CO2-e). A carbon footprint focuses on processes and practices related to the emission of carbon di-oxide (CO2) and other greenhouse gases. In general, carbon footprint has been defined as the quantity of GHGs expressed in terms of Carbon di-oxide equivalent (CO2-e), emitted into the atmosphere by an individual, organization, process, product, or event from within a specified boundary. |

Life Cycle Assessment is one of the methods available to quantify the emission behind a product at the farm gate level. LCA is a whole production chain-oriented approach to quantify all types of GHG emissions responsible for a product. The main strength of this approach is its ability to provide a holistic assessment of the entire production process, in terms of resources used and environmental impacts, as well as to consider multiple parameters (ISO 2006).

In general, studies often differ regarding their focus area (farm/regional/national/global level), their systems under consideration (average dairy systems, conventional versus organic, grass-based versus confined), their scope (different system borders), differences in the functional unit (FU), and the way co-products are handled. Direct comparisons of different LCA studies are hard due to such differences in scope, methodological choices, and assumptions. This method also represents significant challenges, particularly when applied to agriculture, for instance the data intensive nature of the method places limitations on the comprehensive assessment of complex, interconnected food chains. A second difficulty lies in the fact that methodological choices and assumptions – such as system boundary delineation, functional units, and allocation techniques – may be subjective and affect the results.

| Box 2: Life Cycle Assessment (LCA) LCA was originally used to analyze industrial process chains, but has been adapted over the last 20 years to assess the environmental impacts of agriculture. It is an environmental impact assessment tool, a ‘compilation and evaluation of the inputs, outputs and potential environmental impacts of a product system throughout its life cycle’ (ISO 14044:2006, 3.2). The life cycle perspective allows for a comprehensive way of assessment, the possibility of taking the whole production chain into account. Generally, LCA has a product focus, which means that a certain product is at the heart of the analysis.LCA as a tool ‘can assist in the identification of opportunities for improving the environmental performance of products, in informing decision-makers, selection of environmental performance indicators and marketing’ (ISO 14044:2006, Introduction). LCA is one tool among several available the results from which can be used ‘as a part of a much more comprehensive decision process’. ‘It does not address the economic or social aspects of a product but the life cycle approach and method may be applied to these other aspects.’ ISO 14044:2006 describes the LCA requirements and guidelines; ISO14040:2006 describes the principles and framework for LCA. |

GENERAL PRINCIPLES OF LCA METHODOLOGY

The LCA method involves the systemic analysis of production systems, to account for all types of inputs and outputs associated with a specific product within a defined system boundary. The selection of system boundary largely depends on the goal of the study. The reference unit that denotes the useful output of the production system is known as the functional unit that has a defined quantity and quality. The functional unit can be based on a defined quantity, such as 1 kg of a product, an alternate may be based on an attribute of a product or process, such as 1 kg of Fat and Protein Corrected Milk (FPCM).

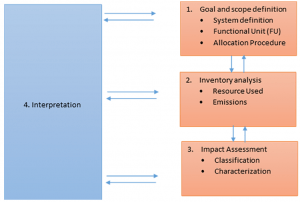

Figure 1. Life Cycle Assessment Framework

Figure 1. Life Cycle Assessment Framework

| Box 3: Estimation of a Functional Unit Usually, in the case of dairy farming, the functional units used to report GHG emissions are kilogram of carbon dioxide equivalents (CO2–eq.) per kg of FPCM (fat and protein corrected milk) and carcass weight, at the farm gate. All milk was converted to FPCM with 4.0 % fat and 3.3 % protein, using the formula: FPCM (kg) = raw milk (kg) * (0.337 + 0.116 * Fat content (%) + 0.06 * Protein content (%)) |

LIFE CYCLE ASSESSMENT (LCA) FRAMEWORK

LCA is organized in four steps (as illustrated in Figure 1): goal and scope definition, inventory analysis, impact assessment, and interpretation. Here is a general description of the methodology.

Definition of Goal and Scope

It defines the frame of the whole analysis. The system borders are drawn, which set the frame for what is included in the analysis and what is excluded. The functional unit (FU) is defined, which expresses resource use and environmental impacts. The impact categories as well as the method of handling multiple products are defined.

Inventory Analysis

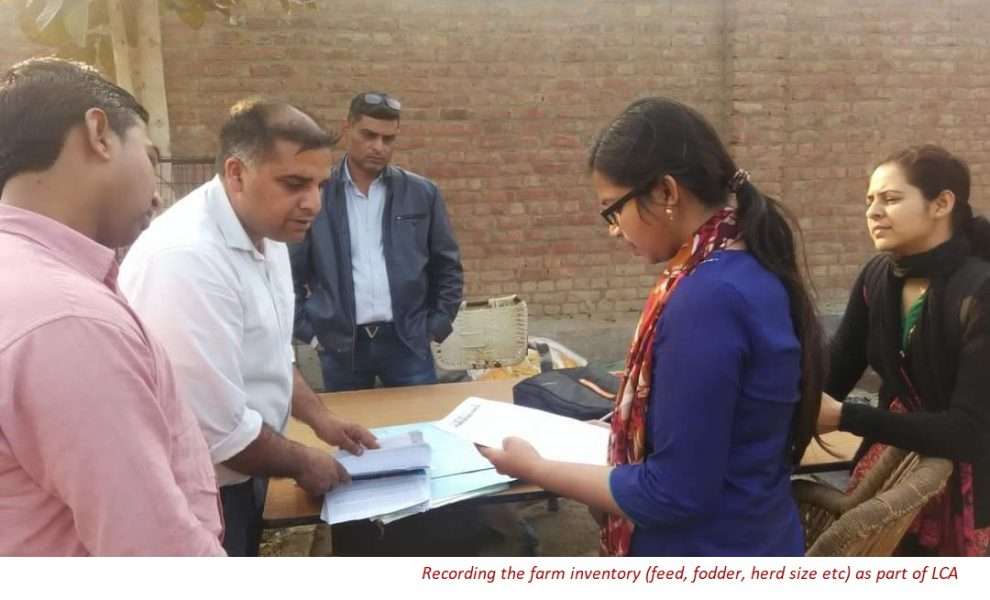

It represents data inventory of all input data. For example in dairy farming, it is feed and fodder use for the animals, as these are mainly responsible for enteric fermentation. Data on consumption of fertilizers, electricity in the farm, manure management system, etc., are needed for the analysis as LCA is a data demanding tool. Furthermore, all resources that are used in the production process at the farm level as well as all emissions are quantified.

Impact Assessment

This is the step where the list that contains the corresponding materials and consumed energy quantities related to the studied product is interpreted and transformed into understandable impact indicators. Total resource used and emissions are calculated and expressed in pre-defined units. Mostly in the study of LCA of milk production, global warming potential (GWP) is the only impact category used for analysis. In order to aggregate these emissions they are converted to the same unit, CO2-equivalents (CO2e) per kg of milk, using the characterization factors in a 100 year perspective provided by the IPCC (Foster et al. 2007), where 1 kg CO2 = 1 kg CO2e, 1 kg CH4 = 25kg CO2e and 1 kg N2O = 298 kg CO2e.

Interpretation

In this last step the result of impact assessment for the different environmental indicators are interpreted and hotspots of emissions are identified in the production or processing chain.

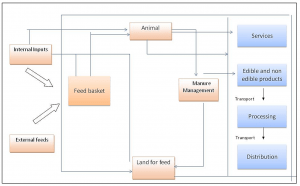

SYSTEM BOUNDARY

The system boundary defines which processes will be included in, or excluded from, the study. Generally, it defines by cut-off criteria, which are parts and materials included in and excluded from the product system. This assessment encompasses a particular boundary and is often termed as system boundary. The cradle to retail system boundary is split into two sub- systems:

- Cradle to farm gate includes all upstream processes involved in livestock production, up to the point where the animals or products leave the farm, i.e., production of farm inputs, and dairy farming.

- Farm-gate to retail covers transport to dairy plants, dairy processing, packaging, and transport to the retail distributor.

Figure 2. System boundary for Life Cycle Assessment

Figure 2. System boundary for Life Cycle Assessment

ALLOCATION OF EMISSION

Allocation is the partitioning and relating of inputs and outputs of a process to the relevant products and by-products. In the case of dairy farming, generally dairy herds produce a mix of goods and services that cannot easily be disaggregated into individual processes. For example, a dairy cow produces milk, manure, capital services, and eventually meat when it is slaughtered. In LCA, we need to use specific techniques to attribute relative shares of GHG emissions to each of these goods and services.

ROLE OF LCA IN RELATION TO PRODUCTS

LCA plays an important role in public and public management of particular products. This may involve both an environmental comparison between existing products and the development of new products, which may also include comparison with prototypes. For instance, a major application involves ‘green’ procurement – that is, a ‘green’ purchasing policy, which can be implemented by both authorities and companies. Another application concerns eco-labelling (i.e., assigning a ‘green label’ to environmentally friendly product alternatives), enabling consumers to make comparisons between products. A further application in relation to products is the design of more environmentally friendly products, otherwise known as eco-design.

LIMITATIONS OF LCA

Though the core characteristic of LCA is its ‘holistic’ nature, which is its major strength, and at the same time, it has limitations also. Most importantly, LCA cannot address localized impacts. It is possible to scale down some of the results and identify the regions in which certain emissions take place, after which differences in the sensitivity of these regions can be taken into account in the context of LCA.

LCA is typically a steady-state, rather than a dynamic, approach. However, future technological developments are increasingly being taken into account in more detailed LCA studies. In general, LCA regards all processes of production as linear, both in the economy and in the environment. Again, some progress is being made in reducing this limitation, but at heart, LCA is a tool based on linear modelling. It focuses on the environmental aspects of products, but says nothing about their economic, social and other characteristics. A further limitation can lie in the availability of data, which is more challenging.

IMPLICATIONS FOR EXTENSION

The main advantage of this approach lies in its ability to easily detect deferrals of environmental loads in the chain. In general, the main aim of using LCA is to reduce the environmental impact of products by guiding the decision making process towards more sustainable solutions. Within the life cycle of a certain product, there is a sequential order of life cycle stages, each one of these phases consumes a certain amount of energy, minerals, water, etc., that subsequently induces a harmful impact on the environment.

With the use of this method Extension researchers can identify the loopholes in the chain or stages from the emission perspective. As this tool is totally inventory-oriented as used in the chain, so the real farm level inventory data analysis can give us an idea about the identification and management of emission hotspots. This analysis helps us to identify the practices most responsible for higher carbon footprint values. This will help researchers to identify potential improvement opportunities of products or processes from the perspective of lower environmental impacts and reduced use of resources across all life cycle stages.

REFERENCES

Flysjö A, Cederberg C, Henriksson M and Ledgard S. 2011. How does co-product handling affect the carbon footprint of milk? Case study of milk production in New Zealand and Sweden. International Journal of Life Cycle Assessment 16: 420-430.

Foster C, Audsley E, Williams A, Webster S, Dewick P and Green K. 2007. The environmental, social and economic impacts associated with liquid milk consumption in the UK and its production. A review of literature and evidence. London: Defra.

Hospido A. 2005. Life cycle assessment as a tool for analysing the environmental performance of key food sectors in Galicia (Spain): Milk and canned tuna. Doctoral Thesis submitted to University of Santiago de Compostela, Santiago de Compostela, Spain.

International Organization for Standardization (ISO). 2006. Environmental management – Life cycle assessment – Requirements and guidelines. ISO 14044. ISO. Geneva, Switzerland.

IPCC Climate Change. 2007. The physical science basis, summary for policy makers. Contribution of Working Group I to the Fourth Assessment Report of Intergovernmental Panel on Climate Change. http:// www.ipcc.ch

Steinfeld H, Gerber P, Wassenaar T, Castel V, Rosales M and de Haan C. 2006. Livestock’s long shadow; environmental issues and options. Rome: Food and Agricultural Organization of the United Nations.

Thomasen M, van Calker K, Smits M, Lepema G and de Boer I. 2008. Life cycle assessment of conventional and organic milk production in the Netherlands. Agricultural Systems 96:95-107.

Vora HN. 2010. Carbon trading for profitability in dairy & agriculture sector. Souvenir of National Seminar: Energy Management and Carbon Trading in Dairy Industry. Anand: SMC College of Dairy Science. Pp.13-17.

Pampi Paul, Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: pampindri@gmail.com)

Mahesh B Tengli, Assistant Professor, MTTC&VTC, College of Fisheries, CAU, Lembucherra-799210 (Email id: mahidxndri16@gmail.com)

Mahesh B Tengli, Assistant Professor, MTTC&VTC, College of Fisheries, CAU, Lembucherra-799210 (Email id: mahidxndri16@gmail.com)

N Uttam Singh, Senior Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: uttamba@gmail.com)

N Uttam Singh, Senior Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: uttamba@gmail.com)

Anirban Mukherjee, Scientist, ICAR Research Complex for Eastern Region, Patna-800014 (Email id: anirban.extn@gmail.com)

Anirban Mukherjee, Scientist, ICAR Research Complex for Eastern Region, Patna-800014 (Email id: anirban.extn@gmail.com)

A Roy, Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: aniruddhaubkv@gmail.com)

A Roy, Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: aniruddhaubkv@gmail.com)

CH Gowda, Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: hrchikkathimmegowda@gmail.com)

CH Gowda, Scientist, ICAR Research Complex for NEH Region, Umiam, Meghalaya-793103 (Email id: hrchikkathimmegowda@gmail.com)

Very good attempt to communicate the utility of a very potential analytical tool for impact assessment/environmental auditing by a team of young inspired scientists working in a remote Research Centre of NARS. Congratulations! Right team to also undertake further detailed studies to empirically illustrate the strength of LCA to what it can presently do with limitations of inability to capture localized impacts, economic, social and other characteristics of environmental processes and products and what it can do when these limitations are relaxed/overcome. Keep it up!

“I appreciate the inquisitiveness of the budding scientists coming out with a blog on the potentiality of LCA to reduce the environmental impacts and also the use of resources. The energy consumption in developed nations is very high compared to developing nations and it is considered as an important indicator for economic development. The energy consumption in a country like India is very low. Lack of data, as pointed out by the authors is the main constraint in the use of LCA or any of these approaches which could be used to quantify various indicators. Developing a reliable database is a must and it needs to be taken very seriously. Congratulations to Drs. Pampi Paul and others on educating us on LCA. Thanks to AESA for publishing it.”